Capabilities

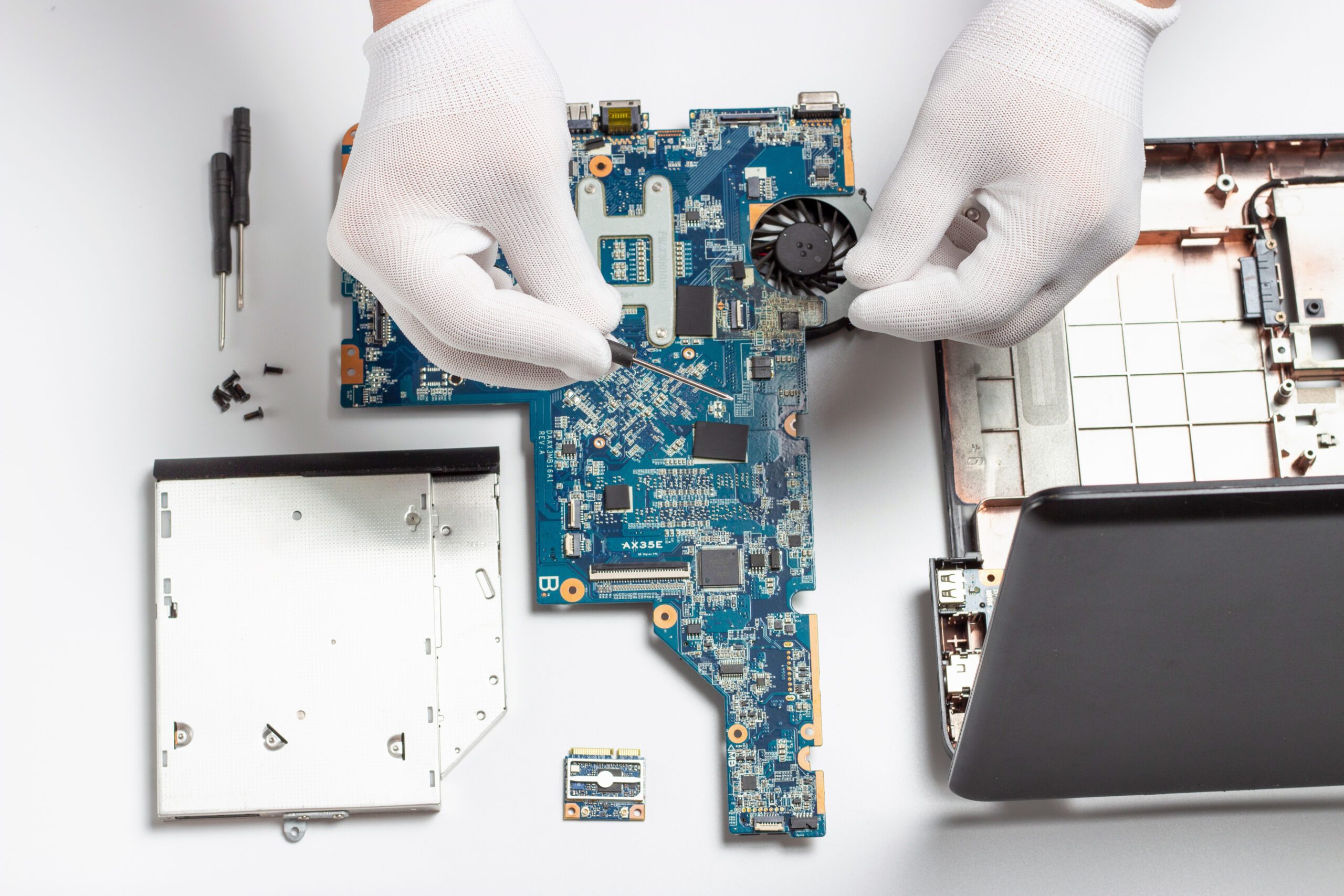

Engineering

Our team of engineers works with you on a customized approach to meet your organization’s objectives for device life-cycle management. Our services and allow organizations the ability to make fiscally responsible decisions in the evolving electronics space.

Research & Development (R&D)

Encore’s R&D department is comprised of Scientists and Engineers with over 15 years of experience in the remanufacturing industry and developed rapport with key technology contacts and suppliers.

We research to define or innovate both existing and non-existent materials, processes, and/or products to support the demands of our customers.

We are proficient in Reverse Engineering, BOM Creation (Bill Of Materials) and validate each process for quality, subjecting each through rigorous Reliability Testing.

New Product/Process Introduction (NPI)

Automation

Our commitment to our customers is to seek and present all opportunities for cost-savings. We developed our Automation Department with this in mind.

Our team comprises creative electronic, electromechanical, mechanical, and system engineers, along with our development department builds strategies to navigate all technological demands.

We utilize CNC Machines and 3D Printers and create in-house systems and JAVA programming, which give us the competitive capacity to make any tool needed for integration.

Our team excels in the Design and Machining of Parts, Hydraulics and Pneumatics, PLC and Microcontroller Programming, Data Manipulation and Analysis with Python programming, Creation of Integration Systems for the user in (JAVA) language, and Management and integration of vision machines.

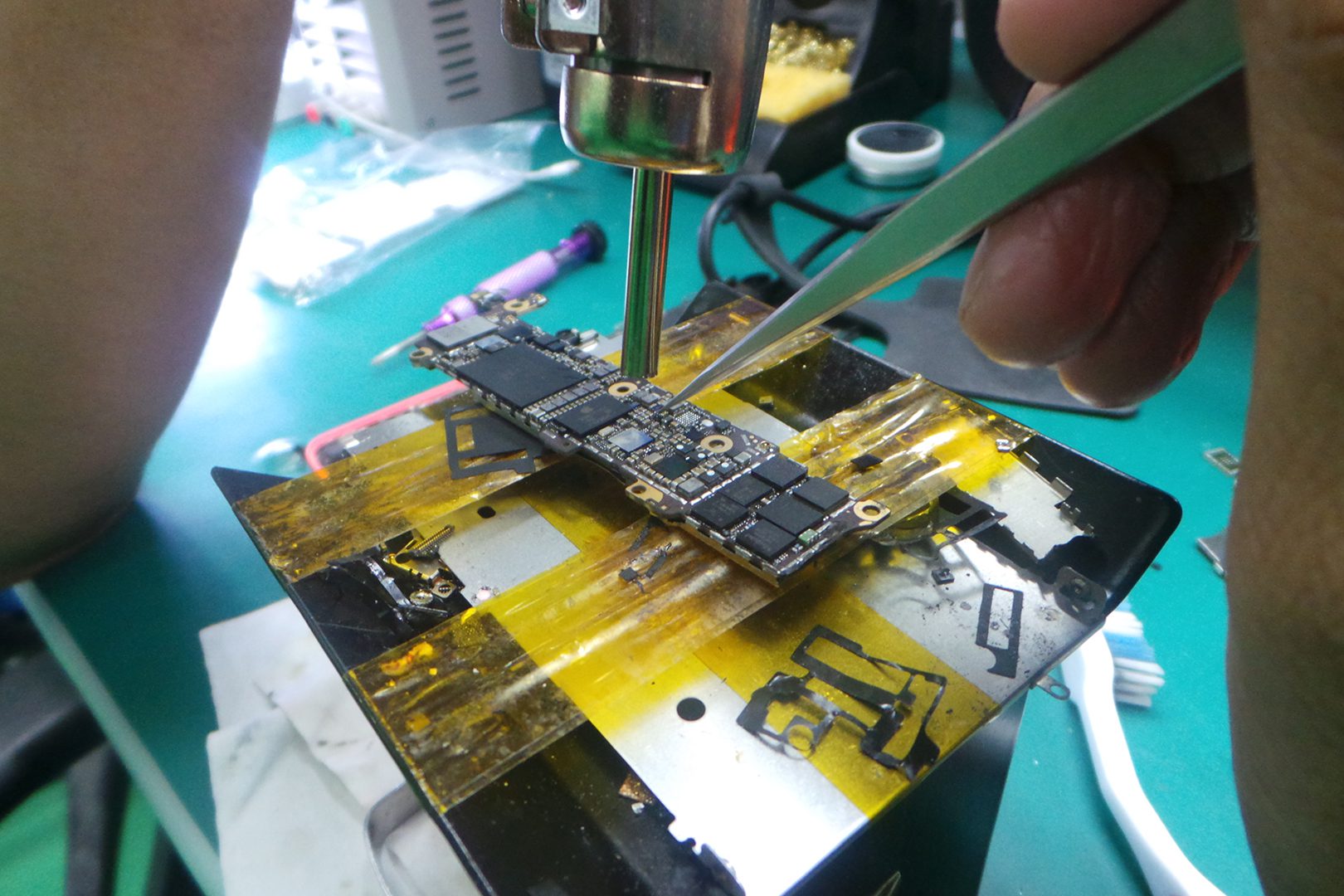

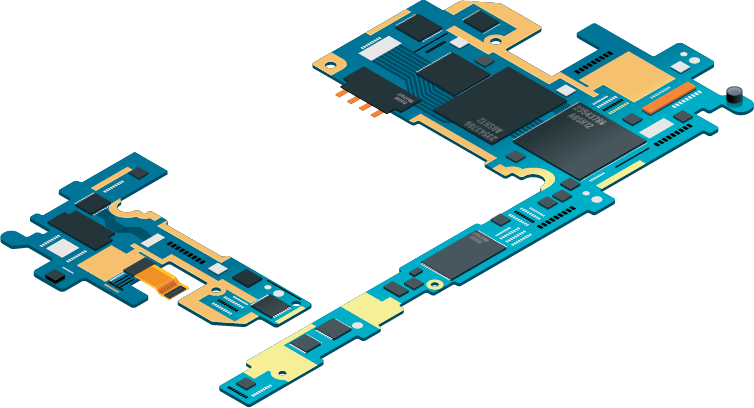

Reverse Engineering

1

The specifications, main parts, characteristics, requirements, and technology types of the product.

2

Dismantle the product until it’s minimum expression to meet and understand their small parts and components.

3

Define the different parts and their configurations. Capture all the information into a Bill of Material (BOM) (explosion View).

3

Develop suppliers and remanufacture process that reach the product specs.

Custom Software

Warehouse Management System (WMS)

Custom Configuration

Instant Reporting

Scalable On-Demand

Connect With The Encore Team

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.